Which Part Of A Rope Is Used For Hoisting

Ever looked at a sturdy rope and wondered about its secrets? It’s more than just a bunch of fibers twisted together! There’s a whole world of engineering and clever design that goes into making a rope capable of lifting heavy loads. This isn't just for sailors or construction workers; understanding how a rope works can make you feel a little bit like a superhero, capable of feats of strength (with a little help, of course!). It’s a surprisingly accessible bit of knowledge that adds a fun layer of appreciation to everyday objects and exciting adventures. Think about it – the next time you see a flagpole being raised, a chandelier being lowered for cleaning, or even a simple swing set, you'll have a secret insight into the reliable backbone of that action!

The Mighty Core: Where the Lifting Happens

So, which part of a rope is actually doing the heavy lifting? Drumroll please… it’s not one single, magical end! Instead, it's the entire structure working in harmony, but there's a very specific element that bears the brunt of the load: the core. Imagine a rope as having a bit of an identity crisis. On the outside, you have the sheath (or jacket), which is like the protective outer layer. This sheath is super important for safeguarding the inner workings and often gives the rope its color and texture. But when it comes to pure, unadulterated lifting power, the real hero is nestled deep inside: the core.

The core is the heart and soul of a hoisting rope. It’s the part that's specifically designed to handle tension and prevent the rope from stretching excessively or breaking under strain. Think of it as the muscles of the rope. Different types of ropes use different materials and constructions for their cores, each offering unique benefits for hoisting. For instance, you might find cores made from incredibly strong synthetic fibers like Dyneema or Spectra, which are known for their immense strength-to-weight ratio and low stretch. These are the kinds of materials used in high-performance sailing, rock climbing, and industrial lifting where every ounce of strength counts.

The Sheath's Supportive Role

While the core is the star of the show for hoisting, the sheath plays a crucial supporting role. It acts like a strong, protective skin. Without the sheath, the core fibers would be exposed to abrasion, UV rays, chemicals, and other damaging elements that could weaken them over time. The sheath also helps to distribute the load evenly across the core fibers, preventing any single fiber from becoming overloaded.

For hoisting applications, the sheath isn't just a passive covering; it's engineered to be tough and durable. Common materials for sheaths include polyester, nylon, or even a blend of different synthetics. The way the sheath is woven also matters. A tight, well-constructed weave offers excellent abrasion resistance, which is vital when a rope is constantly rubbing against surfaces during hoisting. Think of it like wearing a tough pair of gloves when you're working with rough materials – it protects what's underneath.

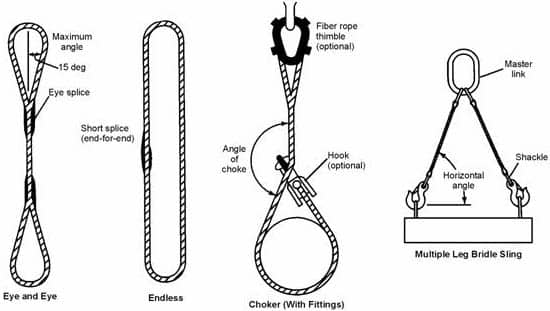

Beyond the Core and Sheath: Knots and Splices

Now, you might be thinking, "What about knots?" This is where things get even more interesting and a little bit humbling for the rope itself. When you tie a knot, you're essentially creating a point of weakness. Knots can reduce a rope's breaking strength significantly, sometimes by as much as 50% or more! So, while we use knots for securing and creating loops, they're not ideal for the actual point of direct hoisting. For serious hoisting, particularly with critical loads, you'll often see splices used instead of knots.

A splice is a way of permanently joining two ends of a rope or forming a loop by interweaving the rope's own strands. A well-executed splice can retain a much higher percentage of the rope's original breaking strength compared to a knot. It's a more elegant and stronger solution for continuous load-bearing situations. So, while you might tie a knot to secure a picnic blanket, for lifting a piano, a carefully crafted splice is the way to go.

The Practical Application

Understanding this distinction between the core, the sheath, and the impact of knots versus splices is incredibly useful. It helps you choose the right rope for the job and use it safely. For instance, if you're building a simple pulley system for your garage, a rope with a strong synthetic core and a durable sheath will perform admirably. If you're involved in activities like sailing or mountaineering, the specific type of core fiber and the way the rope is constructed (e.g., double-braid, single-braid) become even more critical.

The next time you encounter a rope in action, take a moment to appreciate the engineering. The core is diligently bearing the strain, the sheath is offering its robust protection, and if you're lucky, you might even spot a beautifully executed splice doing its secure work. It's a testament to human ingenuity and the power of materials, all bundled up in something we often take for granted. So, the answer to "which part of a rope is used for hoisting?" is really a combined effort, with the core being the primary load-bearing element, supported and protected by the sheath, and ideally connected using a strong splice rather than a load-reducing knot.